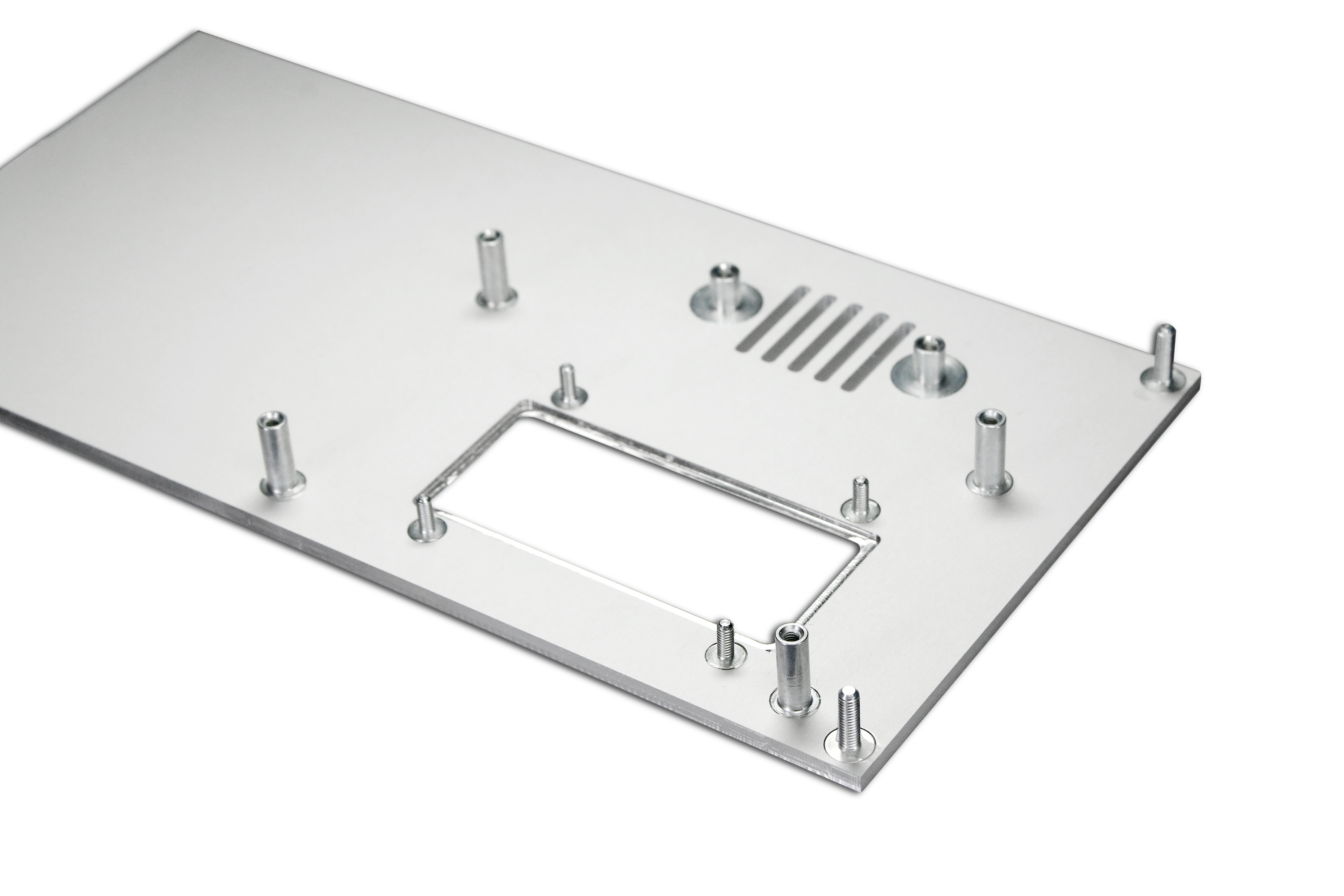

Studs and standoffs

Icon |

Menu bar |

Keyboard shortcut |

|---|---|---|

|

Insert > Studs/standoffs |

I |

Studs and standoffs are available as fastening elements in Front Panel Designer in a standard version and a version for larger loads. The standard studs and standoffs can be bonded or pressed. Passivated nuts are offered as well.

Parameters |

Description |

|---|---|

Type |

|

Thread |

Various metric and inch threads are available according to the load type. Other thread sizes are available upon request. |

Length |

The length that can be selected relates to the geometric length of the stud or standoff (not to the thread lengths). |

Depth offset |

|

Place on reverse side |

Studs and standoffs are placed on the reverse side by default. Remove the check mark if the elements are to be placed on the front side. |

Design information

The studs/standoffs are bonded into cavities by means of a special adhesive. These cavities have a depth of 1.1 mm (standard) or 2.3 mm (load) and, depending on the thread size, different diameters.

So that we can guarantee a secure adhesive bond, it is important that you maintain a minimum distance of 0.5 mm in the plane: between the edge of the cavity and the edge of the front panel or continuous milling elements. Keep this minimum distance of 0.5 mm in the depth as well, between the bottom of the cavity and opposing cavities.