General

Tools and tool change

For the milling elements, the 3 mm cutter is preset as the tool with which the outer contour of the panel is also milled. If you change the elements’ corner radii, a different cutter will automatically be selected in accordance with the radius. If possible, only select a different tool if it is necessary for the contour (for example, to attain smaller radii) since each tool change is included in the price.

Tools and material thickness

To create a new front panel, you must specify a material thickness. With this selection, you also specify the set of tools that is generally available for machining the front panel. Thicker material requires larger tool diameters.

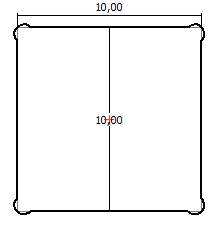

Inner corners of rectangular openings and cavities

Since all the elements will be milled, inner corners are always rounded. Inner corners with “Radius = 0” are produced by using the smallest available cutter (diameter = 1 mm) to reach into the material and round them out:

Edge machining

You can provide the edges of milling objects with a circumferential bevel or rounding. A button for doing so is available in the respective properties dialog.

The option is not available for threaded and countersunk holes.

Offset bevels or roundings (machining only certain sections of the circumferential edge) upon request.

Convert element

The Convert element function can be used to directly convert drill holes and rectangular cut-outs into cavities and vice versa. The function is available in the selected element’s context menu. If an element has properties that cannot be applied to the other object (such as a threaded hole or a cavity with an inner area), the element will not be converted. You will receive a corresponding message.

Subsequently milling elements (for powder-coated panels).

When using a powder-coated base panel, you can check the box in the properties dialog for inserted elements that specifies that inserted elements should only be created after surface finishing. This way you can ensure that threads or fits are available without any constraints. A charge for converting the base panel is made only once in the price calculation.