Drill hole

Icon |

Menu bar |

Keyboard shortcut |

|---|---|---|

|

Insert > Drill hole |

B |

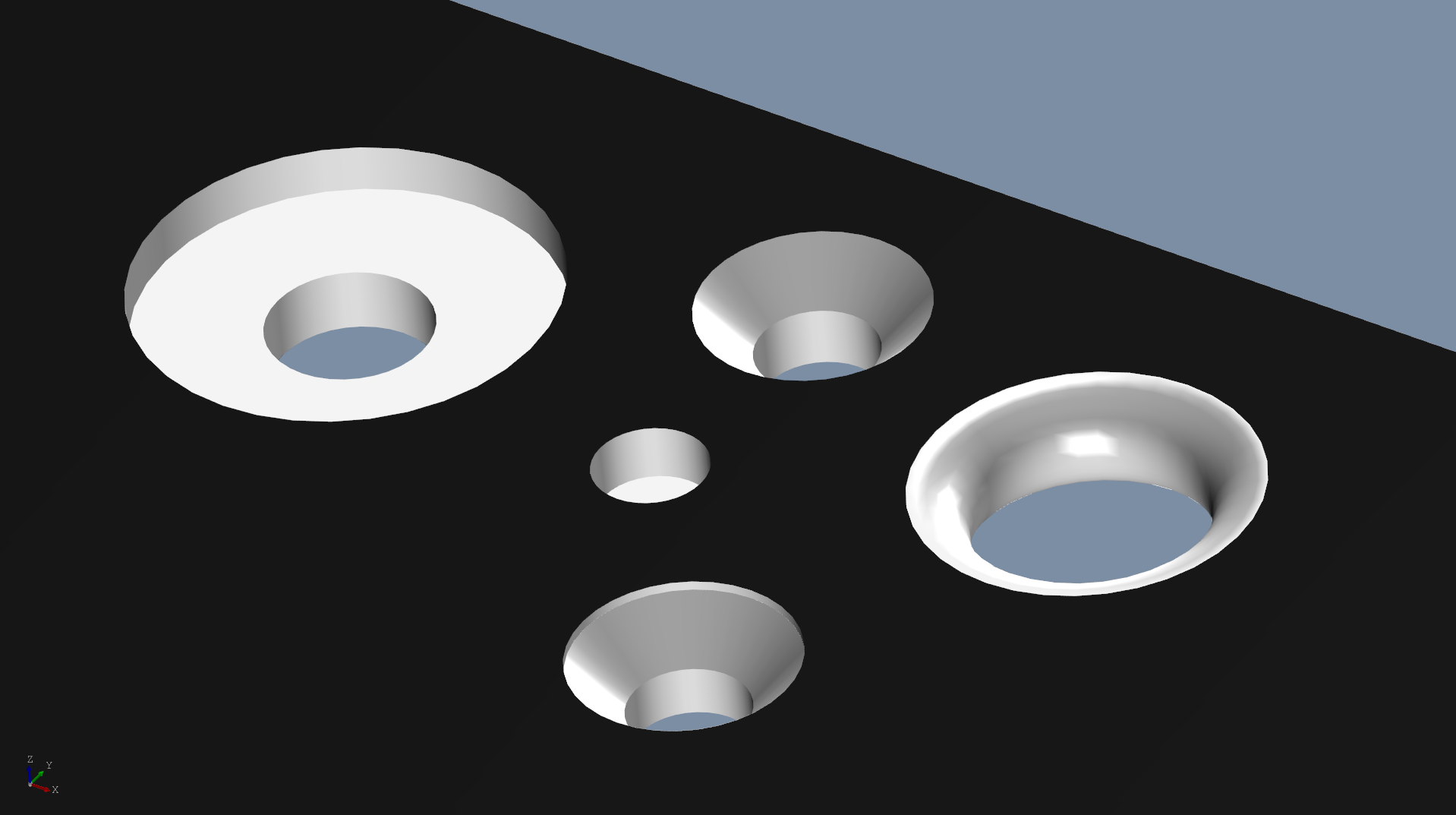

A drill hole is a circular opening that can be designed as a continuous hole or a blind hole (on the front or reverse side of the front panel). Like the other milling elements, it is also machined using a milling tool. You can provide the hole with a beveled or rounded edge, with a thread, or with a countersink.

Function properties

Parameters |

Description |

|---|---|

Diameter |

Diameter of the drill hole. The smallest available cutter diameter is 1 mm. Smaller diameters down to 0.4 mm can be obtained upon request and may involve additional costs. |

Countersink |

Creates a countersunk hole. Countersinks for various standard screws (DIN and ANSI) are available for selection. After specifying the standard, you can specify the thread size of the screw that should fit into the countersunk hole on the right. |

Thread |

Creates a threaded drill hole. Different thread standards (metric and unified) are available for selection. After specifying the standard, you can specify the size of the female thread on the right. Note: As standard, our threads receive a **Protective countersink*. This bevel at the thread inlet makes it easier to fasten the screw. Therefore, in the case of screw holes on the reverse side, it is recommended to also place a continuous threaded drill hole on the reverse side of the front panel if necessary. If you do not want a protective countersink (for instance, because the bevel would leave too few threads for a large thread in a thin panel), write this in the **Remarks for production* field in the front panel’s properties dialog. |

Blind hole |

Produces the drill hole as a blind hole of desired depth on the front or reverse side. |

Place on reverse side |

Check the box next to this option if the blind hole is to be made on the reverse side. |

Cut after surface finishing |

Only for powder-coated panels. Check the box next to this option if the drill hole is to be made after powder-coating. |

Do not produce element |

Check the box next to this option if the element is not to be machined but rather placed on the front panel for information purposes only. |

Edge machining |

The edges on the front and, if necessary, reverse sides can be bevel or rounded. |

Manual sinking parameters |

If you have previously selected a standard countersink, you can manually configure a countersink here. The result is displayed in the preview. |

Manual thread parameters |

If you have previously selected a standard thread, you can enter any pitch for the thread here. You can read the resulting core diameter of the threaded drill hole in the preview. |

Note: You can learn how learn how to insert blind holes into the end faces of the front panel under End face machining.

Tip: To create a Countersunk threaded drill hole proceed as follows:

Place the desired threaded drill hole

Place a blind drill hole with a countersink or edge machining in the same location. Select the depth of the blind hole so that it is identical to the depth of the countersink/edge machining.